Pallet Labeling Solution

Improve Traceability with

Automated Pallet Identification Process

Pallets must be appropriately labeled, whether they are being used for warehouse storage, logistics, or shipment along the supply chain to ensure a seamless delivery while also being immediately identified and traceable.

The Pallet Labeling Solution enables us to recognize pallets coming from various lines, manage print queues, integrate data with the client’s ERP system, and create and generate labels for each logistic unit with all the necessary data. Our automated system can help you save time and lower the possibility of expensive human error if your manufacturing facility produces a range of products for various clients.

What does our solution do?

A fully integrated pallet labeling system increases the productivity of the palletizing process and guarantees that product pallets are appropriately recognized and labeled.

When an incoming pallet arrives, the system recognizes it by I/O connection with an existing PLC or by initiating a scan of the product cases on the pallet.

The system retrieves work order data for the goods on the pallet by connecting to current business systems such as ERP/MES/WMS. SSCC/2D code is then assigned, which is unique and necessary for the pallet label.

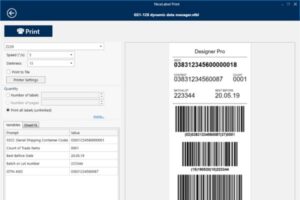

Sets up the printer automatically and sends the label to print. The web UI continually monitors printer status and line control, enabling automatic task selection, label printing and application, and troubleshooting of any line controller or label applicator errors.

After the label has been successfully printed and scanned, the system updates ERP/MES/WMS with finished pallet data and waits for the next pallet.

Features

Pallet StatusKnows when the pallet arrives, what's on it, what has to be printed, and when the labeling process is complete

Pallet StatusKnows when the pallet arrives, what's on it, what has to be printed, and when the labeling process is complete

Search PalletAbility to search completed pallets for reprinting a damaged or lost label

Search PalletAbility to search completed pallets for reprinting a damaged or lost label

Flexible Open ArchitectureEnables interface between the packing process and the WMS

Flexible Open ArchitectureEnables interface between the packing process and the WMS

GS1 ComplianceGenerates code that adheres to GS1 requirements (GS1-128 and SSCC-18)

GS1 ComplianceGenerates code that adheres to GS1 requirements (GS1-128 and SSCC-18)

Seamless IntegrationIntegrates with WMS / ERP systems, making pallets easier to identify in the warehouse

Seamless IntegrationIntegrates with WMS / ERP systems, making pallets easier to identify in the warehouse

Reprint LabelAbility to reprint the pallet label without affecting unique codes

Reprint LabelAbility to reprint the pallet label without affecting unique codes

Benefits

- AccuracyAccurately labels random pallets from multiple production lines

- Full TraceabilityReal-time product traceability, pallet location, and pallet aggregation

- Increased ProductivityInteracts and interfaces with palletizer conveyor controllers with a user-friendly UI and streamlined database connection

- Increased EfficiencyAutomating and centralizing the labelling process effectively

- Cost savingWork seamlessly with real-time data resulting in reduced errors

- Fast return on investmentAutomated processes, manage designs better and increase the overall efficiency

This might interest you

Industries we serve

For large/small scale Manufacturers and Distributors looking to integrate Pallet Labeling with the least amount of investment and turnaround time, we provide a full solution in the form of our ready-to-use Pallet Labeling Solution.

What our customers say

Your company have been great at keeping me in work, they always line something else up.

Your company have been great at keeping me in work, they always line something else up.

Your company have been great at keeping me in work, they always line something else up.

Your company have been great at keeping me in work, they always line something else up.

Pallet labeling software is the solution if you're seeking for a quality, cost-effective automated method of tracking your warehouse inventory.

Contact LabelingOnUs to Learn More